Various Wafers / Windows with Coatings

- Can be used as components for various filters and as windows to protect electronic sensors and detectors from the surrounding environment.

Applications

- Digital Camera

- Digital Camera for Broadcast / Cinema

- Laser Processing Equipment

- Other Sensor Devices

Various Wafers / Windows with Coatings

Features

- We provide high quality quartz crystal wafers cut with high precision at arbitrary angles.

-

We can also provide substrates using "N-Grade EX," an ultra high purity quartz crystal grown with technology developed over many years at NDK.

Those substrates exhibit excellent resistance to laser and in radiation environments. - In addition to quartz crystal substrates, we can provide various optical crystals, optical glass, and absorbing glass.

- AR coatings can be customized according to the wavelength band of use and your desired reflectance characteristics.

Lineup of Optical Wafers That We Can Provide

| Materials | Low α Ray Radiation | Refractive Index nd |

Abbe Number vd |

Specific Gravity [g/cm3] |

Coefficient of Thermal Expansion [x10-6/℃] 300℃ |

Transition Point [℃] |

Knoop Hardness | Max. Size [mm] |

|---|---|---|---|---|---|---|---|---|

| Cryatal Quartz | 〇 | ※1 | ND | 2.65 | - | 573 | ND | ※1 |

| Cryatal Quartz(X-Cut) | 〇 | 1.549 | ND | 9.6 | 100×100 | |||

| Cryatal Quartz(Z-Cut) | 〇 | 1.544 | ND | 16.89 | 6inch | |||

| Lithium Niobate | 2.275 | ND | 4.64 | - | 1140 | ND | 3inch | |

| Sapphire | 1.768 | 72.2 | 3.97 | 5.3 | 2000 | 2200 | 75x75 | |

| Synthetic Quartz | 1.459 | 67.8 | 2.20 | - | ND | ND | 75x75 | |

| N-BK7 | 1.517 | 64.2 | 2.46 | 7.1 | 557 | 610 | 75x75 | |

| B270 | 1.523 | 58.5 | 2.55 | 8.2 | 533 | 542 | 75x75 | |

| D263T eco | 1.523 | 55 | 2.51 | 7.2 | 557 | 590 | 75x75 | |

| D263LA eco | 〇 | 1.523 | ND | 2.51 | - | 557 | ND | 75x75 |

*1 Depends on the cutting angle

Optical wafer transmittance (without coating) comparison

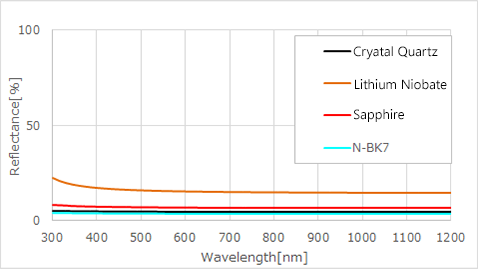

Optical wafer surface reflectance comparison

Various AR Coatings

We can propose and provide AR coatings according to the wavelength of use and your desired optical properties.

Various AR Coatings

Specifications Example

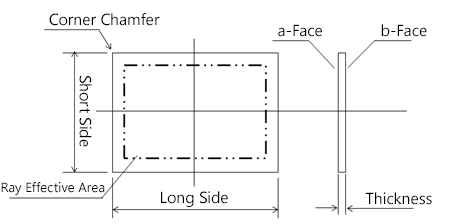

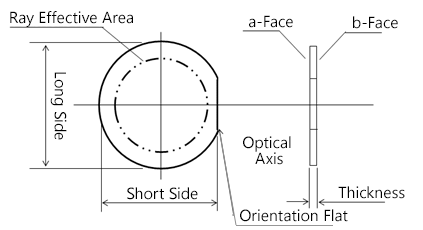

Crystal Window

| External Dimensions | Max. 76.2mm×76.2mm | ||||

|---|---|---|---|---|---|

| External Dimensions Tolerance | ±0.5mm | ||||

| Substrate Materials | Quartz Single Crystal Z Plate | ||||

| Thickness Dimenson | 1mm±0.1mm | ||||

| Coating | a-Face/b-Face With AR Coating Both Side | ||||

| Transmittance | T≧ | 98.0% | @400~700nm | ||

| Surface Reflectance | R≦ | 1.0% | @400~700nm |

*Please inquire for special specifications.

Warranty Items

Test items include temperature, humidity, impact resistance, heat resistance, etc. for the environmental and mechanical properties of optical components.

We set test items and conditions for each component and guarantee the properties of the component. However, warranty items and conditions vary depending on the shape, properties, application, and environment of the optical component.

| Subjected to High Temperature | 85℃ 1000H |

|---|---|

| Subjected to Low Temperature | -40℃ 1000H |

| Subjected to High Temperature and High Humidity | 60℃90%RH~95%RH 1000H |

| Heat Shock | -40℃ 2H 、85℃ 2H、100℃/H 10 Cycles |

| Subjected to Thermal Shock | -40℃/85℃ 30 Minutes Each 100 Cycles |

| Coating Adhesion Strength | Cellophane tape (LP-18) is applied to the component, rubbed with the fingers three times, and then quickly pulled off in a vertical direction ten times |

| Abrasion Resistance | The vapor-deposited surface is pressed with lens-cleaning paper (DUSPER K-3) with a pressing pressure of 4.9 N/cm2 (500 gf/cm2)

1 round-trip/second continuous, round-trip distance 10 mm, 100 round-trips |

| Solvent Resistance Test | Using lens-cleaning paper (DUSPEP K-3) in solvents such as IPA, acetone, ethanol, etc. with 2.94 N (300 gf) 1 round-trip/second continuous, round-trip distance 10 mm, 100 round-trips |

Optical Component