Synthetic quartz crystals are made from natural quartz crystals and recrystallized into high purity quartz crystals with few impurities.

They are used as materials for quartz crystal devices, optical components, etc., and these materials themselves have a significant impact on the characteristics of the products.

Here we introduce NDK's commitment to achieving the highest quality in terms of materials, seed crystals, growth, and craftsmanship by engineers and craftspeople.

Materials

Strict Cmmitment to Materials

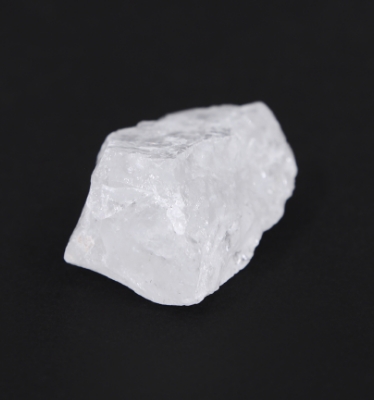

Lascas: Fragments of Natural Quartz Crystal

A Large-scale Open-pit Mining Operation in Brazil

Lascas, which are fragments of natural quartz crystals used as materials for synthetic quartz crystals, are classified into around five grades according to their level of transparency. Grades 2 to 3 are suitable for growing synthetic quartz crystals. If the transparency is poor, the quartz crystals contain cracks and mother liquor from growth, which is not good because they contain more unwanted components such as iron, sodium, calcium, potassium, chlorine, fluorine, etc. In addition, if the transparency is high, the aluminum content will in turn be extremely high. This is because high quality natural quartz crystals grow by taking in aluminum.

Grades of Lascas

Grade 1 (Transparent)

Grade 2 (Translucent)

Grade 3 (White Opaque)

At NDK, we use Grade 2 to 3 lascas from Brazil and Madagascar, where quartz crystals that contain fewer impurities are produced. Prior to shipment, the concentration of impurities in the lascas is analyzed at an analytical laboratory. After confirming that the analysis results meet the concentration standards, the product is finally shipped from Brazil.

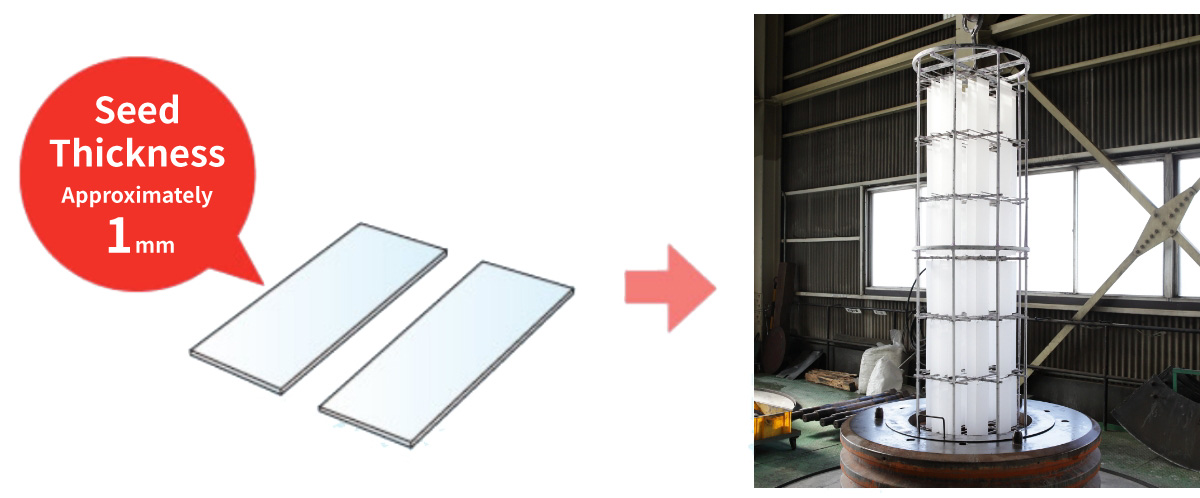

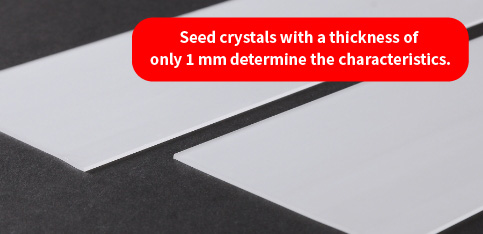

Seed Crystals

Seed Crystals are NDK's DNA

In-house Production of Dedicated Seed Crystals

Installation Spacing Relies on the Experience and Expertise of The Engineer

Growth

One of The World's Largest Autoclaves

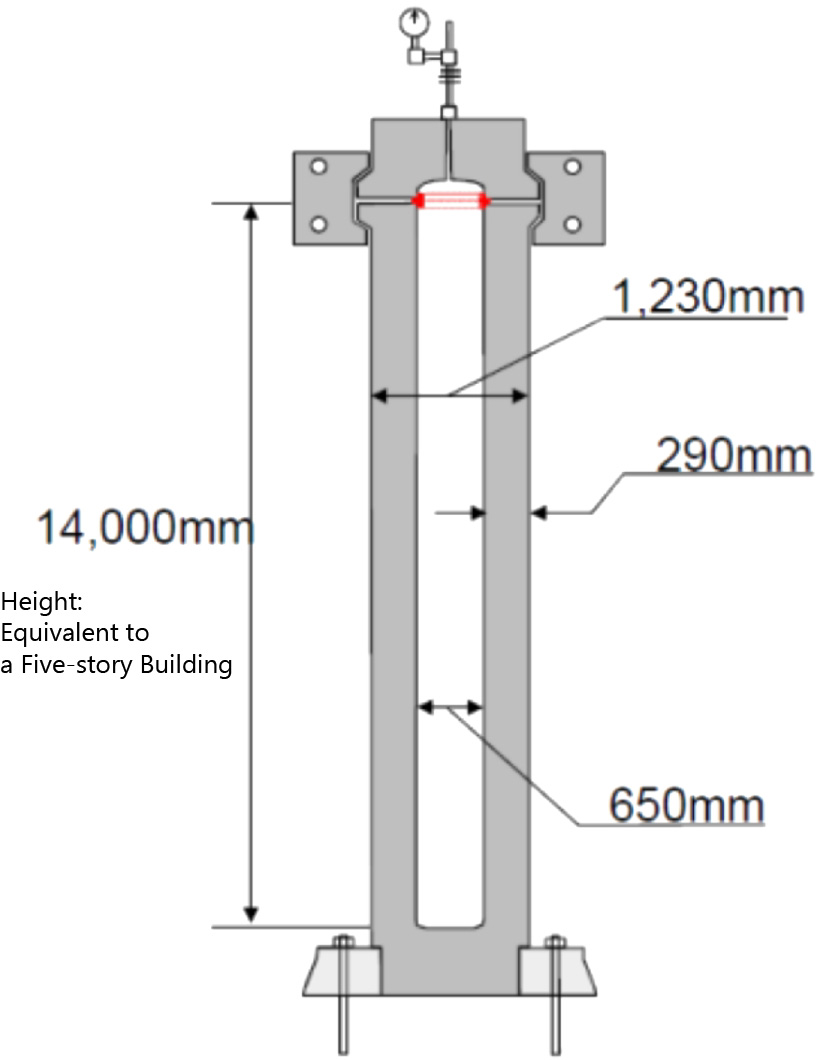

Schematic Diagram of a Large-scale Growth Furnace

(Inner Diameter φ650 mm × 14 m)

NDK's Sayama Plant is equipped with one of the largest autoclaves in the world.

They are 14 meters deep with a total weight of 118 tons, an inside diameter of 65 centimeters, and a wall thickness of 29 centimeters.

The daily growth rate is approximately 0.5 mm.

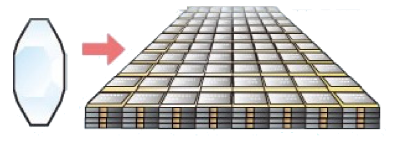

We let them grow in this autoclave for anywhere from a few months to half a year. About two tons of synthetic quartz crystals are produced from a single autoclave. They are all the same size and have the same quality, and hundreds of thousands of quartz crystal parts can be made from a single synthetic quartz crystal.

Number of Quartz Crystal Devices Made from One Synthetic Quartz Crystal

Over100,000

The ability to produce this many at one time is top class in the world.

View Inside the Autoclave

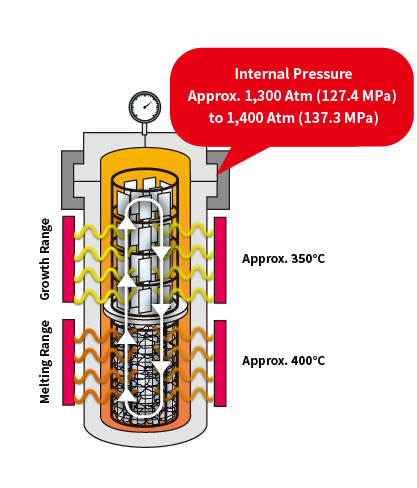

The principle of growing synthetic quartz crystals is to artificially reproduce an environment similar to the process of growing natural quartz crystals inside the earth's crust. When the autoclave is filled with lascas and seed crystals and the temperature at the top of the autoclave is lower than the temperature at the bottom, lascas (material), which is melted under high temperature and high pressure, moves to the top by natural convection. Then, the melted crystals adhere to the top of the seed crystal, which recrystallize on the seed crystal as their base. The pressure inside the autoclave at this time is between 1,300 atm to 1,400 atm.

Craftsmanship

Visualization Techniques to Identify Invisible Growth

Once the lid of the autoclave is closed, the inside cannot be seen during the three to six month growing period. Thanks to years of know-how and master craftsmanship, NDK is able to assess the state of growth and ensure that the quality of the product is exactly as required, even though the inside of the autoclave is not visible.

The growth of crystals is caused by temperature differences in the solution in which the materials are dissolved. The temperature difference of the solution cannot be precisely controlled as the heater deteriorates, so at NDK, we made improvements to it through renovation work in 2017. The temperature of the solution is estimated from the temperature difference on the autoclave surface, but this method is not sufficient. So, in that same year, we devised a new method for predicting the growth rates of the crystals.

With this method, it has become possible to indirectly visualize the growth of crystals inside the autoclave. The growth rate is an important process that affects the "infrared absorption (α3585)" quality and frequency-temperature characteristics of synthetic quartz crystals.

Convection Stabilization of Solutions that Determines Quality

In addition to the seed crystals, another factor that determines quality is the stability of convection of the solution inside the autoclave. At NDK, we use convection control plates (baffles) with independently developed structures for each growing specification to control the convection of the solution according to the required quality of synthetic quartz crystal.

Craftsmanship that Supports the Quality of NDK's Synthetic Quartz Crystals Behind the Scenes

High quality synthetic quartz crystals cannot be grown just by using sensors and controls.

Each autoclave has its own exquisite peculiarities, and it is up to the experience and skill of the craftsman to grasp them and adjust the temperature and convection. The quality of the product is greatly determined by the accuracy of the fixing of the lids, as the pressure inside can reach as high as 1,500 atm. They must be tightened with an accuracy of 1/100th of a millimeter, and this process cannot be mechanized because it requires subtle human manipulation.

Micron-level Maintenance that Creates a Difference in the Finished Product

An autoclave is a so-called "pressure cooker" that is used at high temperatures and pressures. Therefore, if the precision of maintenance is inadequate, it will not be able to withstand the high pressure conditions, causing the filled solution to leak out from the sheet area. If the solution leaks, the internal pressure drops, which may result in the suspension of growth, and in the worst case scenario, the leak will cause a break in the sheet area. At NDK, autoclaves are maintained only by workers with extensive experience in maintenance techniques, and as a result, there have been no leaks from the sheet area for several years.

Quality Assessment of Synthetic Quartz Crystals

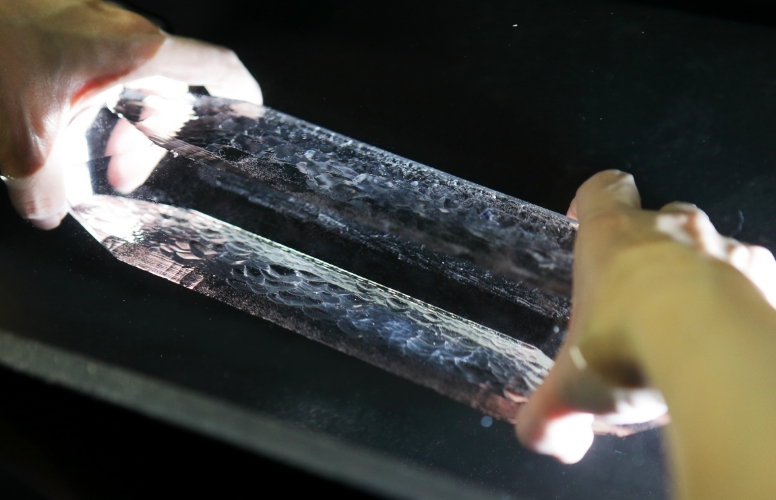

The completed synthetic quartz crystals are inspected in-house according to the quality standards set forth by JIS.

The inside of the quartz crystals is visually inspected by permeating the gemstones underwater and shining light on them to inspect for inclusions, etch channels, etc. In addition, for the alpha value (Q value), a sample is cut from the specified target rough stone and measured in-house using a measuring instrument. (In some cases, we may request an external institution to assess synthetic quartz crystals with specifications that require impurity analysis (such as high-purity).)

Synthetic quartz crystals are not only NDK's DNA, but are also the crystallization of NDK's technology and human power.

Synthetic Quartz Crystal